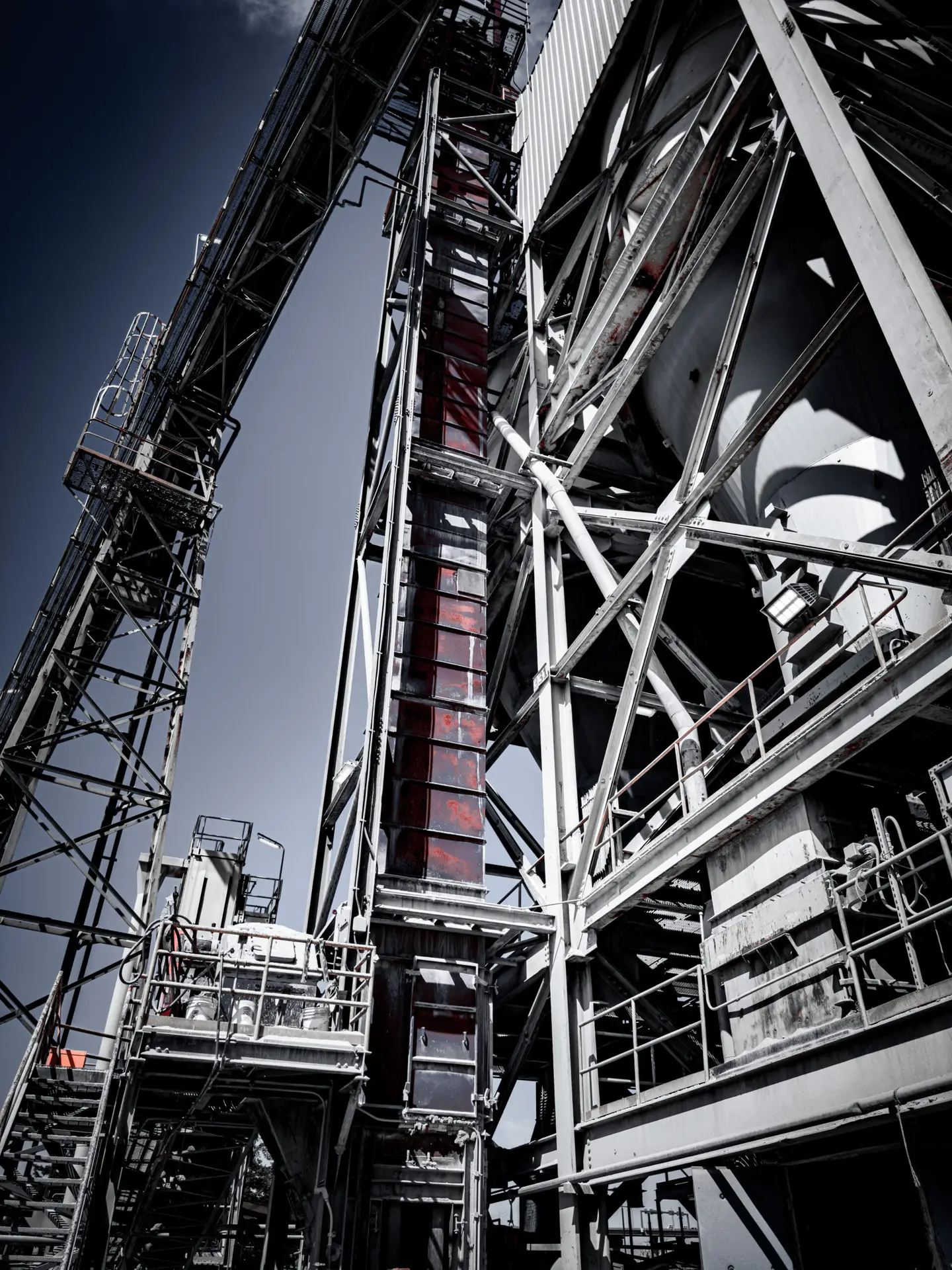

A bucket elevator is a piece of mechanical equipment used to convey bulk materials vertically, from a lower level to a higher level. It is commonly used in industries such as agriculture, mining, and manufacturing to move materials like grains, coal, and minerals. Bucket elevators are versatile, efficient, and safe to use, making them a popular choice for many applications.

Working Principle

The basic working principle of a bucket elevator is straightforward. It consists of a series of buckets attached to a belt or chain that is driven by a motor. The buckets are designed to scoop up materials from the bottom of the elevator and transport them vertically to the top, where they are discharged.

The elevator can be either continuous or batch-oriented. Continuous bucket elevators are used for handling larger volumes of materials at a steady rate, while batch bucket elevators are used for smaller volumes of materials that require intermittent handling.

Types of Bucket Elevators

There are three main types of bucket elevators: centrifugal, continuous, and positive discharge. Each type has unique features and is suitable for specific applications.

Centrifugal Bucket Elevators

Centrifugal bucket elevators are the most common type and are used for handling heavy and abrasive materials such as grains, coal, and minerals. They are designed to operate at high speeds, using centrifugal force to discharge materials at the top of the elevator. The buckets are spaced apart and mounted on a chain or belt that is driven by a motor. The centrifugal force causes the material to be thrown out of the bucket, which then returns to the bottom of the elevator for another cycle.

Continuous Bucket Elevators

Continuous bucket elevators are used for handling fragile materials such as food products, fertilizers, and pharmaceuticals. They are designed to operate at slower speeds, using a continuous belt or chain to convey materials vertically. The buckets are closely spaced together, and the material is gently discharged at the top of the elevator.

Positive Discharge Bucket Elevators

Positive discharge bucket elevators are used for handling sticky or viscous materials that tend to stick to the buckets or walls of the elevator. They are designed with a discharge mechanism at the top of the elevator that ensures the material is fully discharged from the buckets. The buckets are closely spaced together, and the material is discharged using a rotary feeder or other mechanical means.

Components of Bucket Elevators

Bucket elevators are made up of several components that work together to transport materials vertically. These components include:

1. Buckets: The buckets are the main component of the elevator and are used to scoop up and transport the material.

2. Belt or Chain: The belt or chain is used to drive the buckets and transport the material vertically.

3. Head Section: The head section of the elevator is located at the top and contains the motor, gearbox, and other mechanical components.

4. Boot Section: The boot section of the elevator is located at the bottom and contains the inlet, discharge, and tensioning mechanism.

5. Intermediate Sections: Intermediate sections are used to provide support and maintain proper tension on the belt or chain.

6. Casing: The casing surrounds the elevator and prevents material from spilling out.

7. Drive and Tensioning Systems: The drive system is responsible for powering the elevator, while the tensioning system maintains proper tension on the belt or chain.

Maintenance and Safety Considerations Bucket elevators require regular maintenance to ensure safe and efficient operation. The following maintenance and safety considerations should be taken into account:

1. Regular inspection of all mechanical components, including the belt or chain, buckets, and drive and tensioning systems.

2. Lubrication of all moving parts to reduce wear and tear.

3. Regular cleaning of the elevator and removal of any debris or material buildup.

4. Proper training of operators on safe operation and maintenance procedures

Additional safety procedures to consider when operating and maintaining a bucket elevator:

1. Always follow the manufacturer’s instructions for installation, operation, and maintenance of the equipment.

2. Ensure that all guards and safety devices are in place and working properly before operating the bucket elevator.

3. Train all operators and maintenance personnel on the proper use and maintenance of the equipment.

4. Use lockout/tagout procedures to prevent accidental startup during maintenance or repair activities.

5. Never overload the elevator or exceed its capacity limits.

6. Regularly inspect the elevator for any signs of wear or damage, such as cracks or deformation in the buckets or belt/chain.

7. Keep the work area around the elevator clean and free of debris to prevent slips, trips, and falls.

8. Wear appropriate personal protective equipment, such as gloves and eye protection, when working on or around the elevator.

9. Use caution when working with materials that are flammable, explosive, or toxic, and follow all appropriate safety procedures.

10. Have an emergency plan in place in case of equipment failure or other emergency situations.

By following these safety procedures, you can help ensure the safe and efficient operation of your bucket elevator.

Monthly Industry Information Plus Special Deals on Parts & Services!!