Belt cleaners and scrapers are essential components in industrial

applications, ensuring conveyor belts remain clean and efficient. By removing debris and build-up from the belts, these tools significantly reduce the risk of belt slippage and material carryback, which can cause costly downtime and equipment damage. A clean belt not only enhances operational efficiency but also promotes a safer work environment by minimizing the risk of accidents and injuries due to material spillage. Furthermore, maintaining clean belts extends their lifespan, reducing the need for frequent replacements and lowering maintenance costs. Investing in high-quality belt cleaners and scrapers is a cost-effective strategy that boosts productivity and safety in industrial operations.

Revolutionizing belt cleaning—no more hunting for replacement blades!

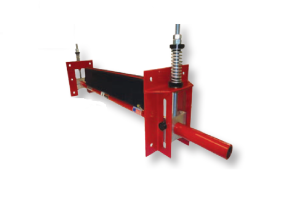

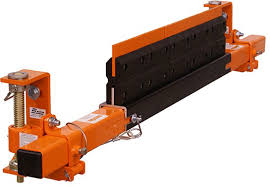

The American Eagle Uni‑Blade is a next‑generation primary belt cleaner that eliminates costly blade replacement guesswork.

The patented bolt-on system (PN 12246927) allows you to upgrade any primary cleaner—no matter the OEM—with a sturdy urethane blade that installs in minutes using standard hardware.

Universal retro‑fit design: Simply share your current cleaner model and we’ll tailor the Uni‑Blade to match—bolt-on compatibility, without adapters.

No special tools required: Installs via standard nuts & bolts—no clamps, cartridges, or tension tools needed.

Custom blade width: Tailored to your exact material path—removing smiley-curve blade ends for better contact, longer life.

Patented bolt-on replacement: Replace the entire blade as a single unit—no parts ordering—just loosen bolts, swap blade, and re-tighten.

Quality urethane options: Choose between standard orange or blue Ev‑R‑Wear, engineered for high abrasion environments.

MSHA-ready: Compatible with rugged belt applications, including mine-duty requirements.

OEM compatibility: Serves as a direct replacement for Martin® QC1HD/PD, Argonics™ Eraser RPQ/Eraser™, Asgco® Skalper® III/IV, Benetech® BEP1, Flexco® EZP1/MSP, Mato MDP185, Superior Exterra®, and many, many more!

Argonics Eraser PQ |

Argonics Eraser RPQ® |

Argonics Eraser |

Argonics MES |

Argonics Micro Eraser |

Asgco® Mini Skalper® |

Asgco® Pit Skalper® |

Asgco® Skalper® III & IV |

Benetech® BEP1 |

Flexco® EZP1 |

Flexco® EZP-LS |

Flexco® MSP |

Martin® PV |

Martin® QC1+HD® |

Martin® QC1+PD® |

Martin® QC1+PV |

Martin® QC1HD® |

Martin® QC1 |

Mato MDP120 |

Mato MDP185 |

Superior Exterra® |

Primary cleaners are the first line of defense in maintaining the cleanliness and efficiency of conveyor belts in industrial settings. Installed at the head pulley, these cleaners effectively remove the bulk of material carryback, preventing it from adhering to the belt and causing operational issues. By ensuring the belt is free from large debris and build-up, primary cleaners significantly reduce the risk of belt slippage and material spillage, contributing to a safer work environment. This proactive approach not only minimizes maintenance downtime but also extends the lifespan of the conveyor belt, leading to substantial cost savings. Investing in robust primary cleaners is essential for optimizing productivity and ensuring the smooth, safe operation of conveyor systems in any industrial application.

Secondary cleaners are crucial for enhancing the performance and longevity of conveyor belts in industrial environments. Positioned after the primary cleaner, these cleaners provide a second level of cleaning, effectively removing any remaining fines and smaller debris that the primary cleaner might have missed. This thorough cleaning process ensures the conveyor belt operates smoothly, reducing the risk of material buildup that can lead to belt slippage and potential system failures. By maintaining a cleaner belt, secondary cleaners help to create a safer workplace by minimizing hazards associated with material spillage. Additionally, they contribute to lower maintenance costs and extended belt life, resulting in significant financial savings. Implementing high-quality secondary cleaners is a smart investment for any industrial operation, enhancing both safety and efficiency.

Tertiary cleaners are essential for achieving the highest level of cleanliness and efficiency in conveyor belt systems used in industrial applications. Positioned further along the conveyor line, these cleaners are designed to remove the finest residual materials that primary and secondary cleaners may miss. By ensuring a virtually spotless belt, tertiary cleaners help prevent any material buildup that could compromise the belt’s performance and lead to operational disruptions. This comprehensive cleaning approach not only enhances the efficiency of the conveyor system but also promotes a safer work environment by significantly reducing the risk of material spillage and associated hazards. Additionally, keeping the belt in optimal condition with tertiary cleaners extends its lifespan, reducing the need for frequent maintenance and replacement, thereby saving costs. Investing in high-quality tertiary cleaners is crucial for maximizing productivity and safety in industrial operations.

Specialty belt cleaners, such as the American Eagle Manufacturing Poly-Star, offer unparalleled efficiency and durability for conveyor systems in industrial applications. Designed with innovative Poly-Star technology, these cleaners provide exceptional cleaning performance, effectively removing even the most challenging materials from the surface of cleated belts. The unique design ensures minimal wear on the belt, significantly extending its lifespan and reducing maintenance needs. By maintaining a pristine belt, specialty cleaners like the Poly-Star contribute to a safer work environment, minimizing the risk of material spillage and associated hazards. Additionally, these high-performance cleaners help optimize conveyor system efficiency, leading to reduced downtime and increased productivity. Investing in specialty belt cleaners like the American Eagle Manufacturing Poly-Star is a strategic move for industrial operations seeking superior cleaning solutions for challanging applications.

At The ACT Group, we recognize the paramount importance of collaborating with trusted vendors and parts providers who deliver quality materials at competitive prices. Our commitment to excellence is fortified by enduring relationships cultivated over the long term with our partners. These partnerships are founded on mutual trust, reliability, and a shared dedication to delivering top-tier solutions to our customers.

By sourcing materials from reputable suppliers who adhere to stringent quality standards, we ensure that every component meets or exceeds industry requirements, ultimately guaranteeing the reliability and longevity of our products and services. Customers can rest assured that when they choose ACT, they are not only gaining access to cutting-edge solutions but also benefiting from our unwavering commitment to integrity and customer satisfaction. With ACT, trust is not just a promise; it’s a cornerstone of our business philosophy.

Belt Cleaners & Accessories, Belt Alignment, Belt Support, Sealing Systems, Tail Protection, and Accessories. American Eagle has you covered in the transfer point. As the leader in urethane technology, wear products come second nature to AEM. Keep material on the belt where it belongs, with the help of American Eagle

Pulleys, Lagging, CEMA ‘B’, ‘C’ and ‘D’ Idlers, Conveyor Covers, Idler Guarding, Magnetic Separators, Take-Ups, and additional conveyor accessories.

Global Manufacturing will assist you in finding economical solutions to your flow problems using our comprehensive line of Industrial Vibrators and Air Cannons. Frequently problems causing major industrial aggravations actually cost very little to fix. Our solutions are not complicated.

The world leader in composite idler technology and manufacture of the One-Man Idler, Enduride brings the latest technology to you. MSHA approved, CEMA C, D & E and F. Why stop at MSHA Approved Idlers? Enduride has a MSHA RECCOMENDED safety netting, which revolutionizes your plant safety and Preventive Maintenance program.

Minet was founded in 1947 with one aim: to manufacture conveyor belt fasteners, and quality splices adapted to the needs, and easy to use. Manufacturer of the one and only Superscrew® fastener, the only fastener as strong as a vulcanized splice!

Full line of Grade 2, Grade 1, and Heat Resistant belting. Carrying a wide variety of carcass types and cover compounds. Over 20,000 feet stocked in our Fontana warehouse.

Dust Suppression Systems, Dust Suppression Chemical, Fog Cannons, Air Cannons, Transfer Point Technologies, and Conveyor System Fabrication.