Air Cannons, also known as air blasters, are powerful devices engineered to tackle dust issues at their source. These innovative tools efficiently dislodge material build-up in chutes, silos, and transfer points, preventing the release of airborne dust. Strategically placed and properly designed Air Cannons are essential components of your dust suppression strategy. Key considerations include chute design, impact support, sealing systems, and belt tracking. Discover how Air Cannons can revolutionize your dust control efforts.

ACT proudly features a team of seasoned professionals who excel at delivering top-tier Air Cannon solutions. Our Sales, Engineering, Projects, Shop, and Field personnel are renowned for their professionalism, courtesy, and commitment to ensuring customer satisfaction. With over two decades of experience, ACT has established a reputation for providing trustworthy and cost-effective services. We offer a comprehensive range of Air Cannon services, including turnkey project design, system proposals, and individual part sales. Partner with our Air Cannon experts to address your unique needs, no matter the scope.

Whether you’re grappling with airborne dust challenges or seeking permanent dust control solutions at transfer points, ACT’s Air Cannon technicians will assess your material handling processes comprehensively. Expect a detailed report of findings along with expert recommendations on how Air Cannons can effectively suppress and control dust emissions. Our tailored solutions maximize efficiency and minimize dust-related issues.

After acquiring an ACT Air Cannon system, explore our Air Cannon Service Contract options with your ACT Sales Representative. Our team offers flexible servicing plans, including bi-monthly or monthly schedules, designed to align with your usage patterns. By ensuring material flow and optimizing plant operations, our service contracts provide long-term peace of mind.

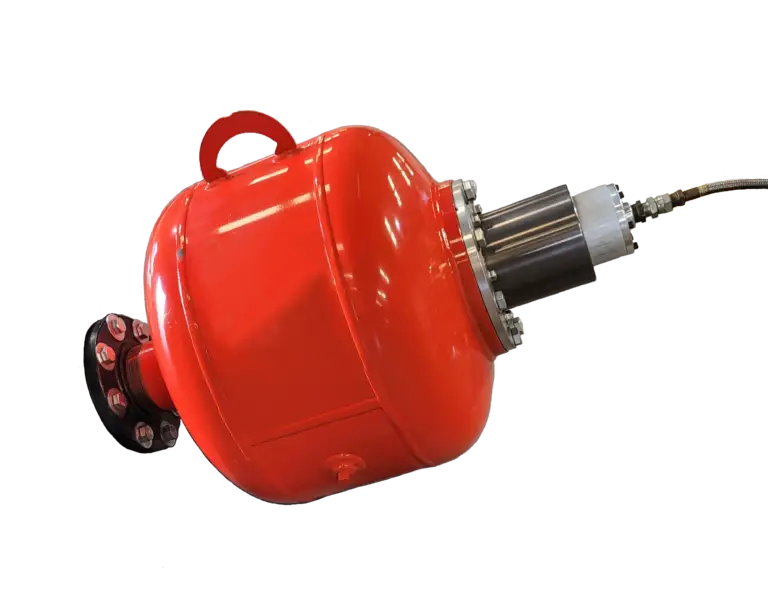

The Flash Air Cannons are blast aerators consisting of a compressed air reservoir with a quick opening valve that releases the stored air in a sudden, high-energy blast. This blast is directed through a discharge pipe to aerate and dislodge material and restore flow.

In a direct blast Air Blaster the air in the reservoir or tank passes directly into the discharge pipe without bends or obstructions in the air course that impede the flow of air. This is important because the quicker the air discharges, the greater the velocity and force of the blast and, therefore, the greater the amount of material affected.

When used in combination, multiple Air Blasters can restore flow to hundreds, thousands, or millions of cubic feet of material. Air Blasters are activated manually or by a micro-controller based sequencing timer that controls the firing time interval and sequence of one or more Air Blasters.

Are you paying too much for replacement valves on your Air Cannon? Did you wish there was an easy solution that didn’t require an investment into a whole new system? Is it even possible to make something MORE powerful than the Hurricane? More reliable? You’re in luck…

Introducing, The Flash Retrofittable Air Cannon Retro System. This system was specifically designed to provide an alternative to Martin Hurricane® replacement valves and can be installed in any Hurricane® tank. In collaboration with ACT, this Global US patented technology overcomes numerous short comings in currently available air cannons from all manufacturers. We accomplished all of this with a simple goal; create a reliable product at the best possible price for our customers. After 3-1/2 years of work with Global Manufacturing the answer is finally here.