The expert team of field technicians at Applied Conveyor Technology specializes in the installation of new projects, routine inspections, maintenance contracts, and 24/7 emergency responses for dust control equipment — with a particular focus on baghouses, bin vents, and ducting systems.

Our field crew is fully equipped to handle any dust collection project, big or small. Dispatched from both Northern and Southern California, our teams provide services across California, Nevada, Oregon, and Washington, ensuring optimal operation of baghouse and bin vent systems and the integrity of ducting for industrial ventilation.

When we started in 1991, The ACT Group initially provided engineering services to the dust collection and industrial ventilation market, primarily in the Western States, and gradually expanding to the whole of the United States. Our Engineering Team has a combined experience of over 75 years in industrial ventilation. We are here to help you through the most challenging applications, big or small!

The ACT Group Engineering and Consultative team is always ready for a new challenge. Specializing in a wide range of disciplines, we are able to offer the following services:

• Engineering of Industrial Ventilation Systems

• System Analysis & Engineering

• Dilution Systems

• Local Exhaust Systems

• Cutting Table & Portable

• Fume Extraction Systems

• Providing MERV 15 Filtration Efficiency

Dust suppression and dust collection are two distinct approaches employed in managing airborne particles and improving air quality in various industrial and construction settings. Each method has its unique mechanisms, applications, and benefits, tailored to suit different operational needs and environmental conditions.

Dust suppression focuses on controlling the spread of dust particles at their source before they become airborne. This method typically involves the use of water, chemicals, or a combination of both to prevent dust from rising into the air. Water sprays, misting systems, and foam applications are common dust suppression techniques. The water or chemical solutions work by capturing dust particles and weighing them down, effectively preventing them from dispersing into the environment. This method is particularly effective in outdoor operations such as mining, construction, and demolition, where controlling dust spread is crucial for environmental health and worker safety. Dust suppression is a straightforward approach that can be quickly implemented to manage dust in large areas.

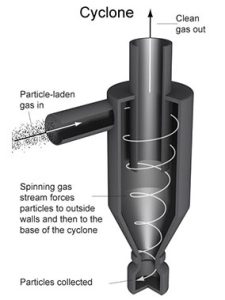

On the other hand, dust collection takes a different approach by targeting airborne particles. This method uses fans, filters, and air flow systems to capture and filter dust from the air, trapping it in a collection system for disposal or recycling. Dust collection systems, such as baghouses, cartridge collectors, and cyclones, are designed to handle various volumes and types of dust. These systems draw in dirty air, pass it through filters that capture the dust particles, and then release clean air back into the environment or workplace. Collection is highly effective in indoor settings or in processes that generate a significant amount of particulate matter, such as woodworking, metalworking, and manufacturing. It is a critical component for maintaining air quality and ensuring compliance with health and safety regulations.

In summary, while dust suppression aims to prevent dust from becoming airborne by using water or chemicals to settle dust particles, dust collection focuses on capturing and filtering airborne dust through mechanical means. The choice between dust suppression and dust collection depends on the specific requirements of the operation, including the type of dust, the working environment, and regulatory obligations. Both methods play vital roles in managing dust emissions, protecting worker health, and preserving environmental quality.